본문 영역

Products

Introducing ESE Solution’s Products.

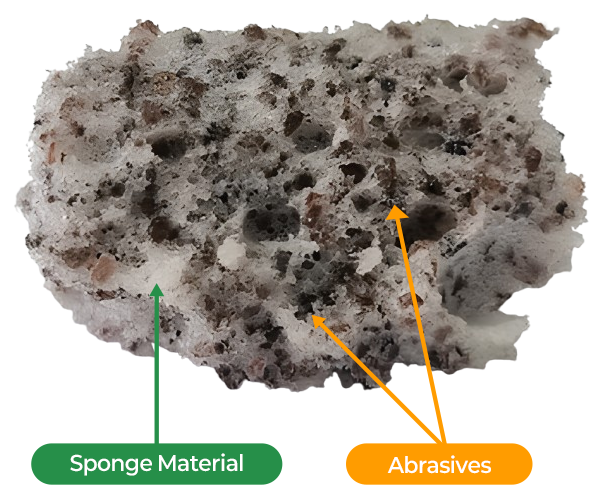

Sponge Media

Superior Surface Preparation

- Sponge Media using Aluminum Oxide as an abrasive can produce surface roughness of 0 ~125 ㎛.

- It also ensures surface cleanliness up to Sa3 / SP5.

- It can be reused up to 10 times with a dedicated Recycler.

- Sponge Media using Garnet, Steel Grit, Glass Bed, etc. as abrasives can be used for a variety of purposes.

| Product Name | Base Material | Bag Weight (kg/bag) | Application | Profile(㎛) |

|---|---|---|---|---|

| SMA 16 |

Aluminum Oxide 14/24 |

18.0 | SMA 16 is recommended when very rough surface roughness is required during industrial surface preparation. SMA 16 is very suitable for removing very hard coating films or requiring surface roughness of 75 μm or more, such as TSA. SMA 15 can be achieved surface cleanliness up to Sa 2½ or Sa 3. |

80-125 |

| SMA 30 |

Aluminum Oxide 30/40 |

18.0 | SMA 30 is the most commonly used Sponge Media for industrial coating removal and surface preparation. On steel SMA 30 removes mill scale, rust and paint coatings and can be achieved surface cleanliness up to Sa 2½ or Sa 3. |

60-80 |

| SMA 60 |

Aluminum Oxide 60/80 |

13.5 | SMA 60 is suitable for removing one or two layers of coating or blasting welding lines. SMA 60 is also designed to remove coatings from aluminum materials or form intermediate surface profiles. SMA 60 can be achieved surface cleanliness up to Sa 2½ or Sa 3. |

40-60 |

| SMA 80 |

Aluminum Oxide 80/100 |

13.5 | SMA 80 is suitable for blasts such as aluminum, wood, and stonework. In particular, SMA 80 is designed to be suitable for requiring surface roughness below a designated profile such as aluminum. |

30-50 |

| SMA 120 |

Aluminum Oxide 120 |

13.5 | SMA 120 is the choice when selective coating or corrosion removal and minimal surface roughness are required. It can be used to remove thin coatings from steel/aluminum or to give roughness to previously painted surfaces. |

20-30 |

| SMA 220 |

Aluminum Oxide 220 |

9.0 | SMA 220 is suitable for light cleaning of sensitive metal composites and other materials or for cleaning turbines. | 10-15 |

| SMA 320 |

Aluminum Oxide 320 |

9.0 | SMA 320 is designed for the treatment of sensitive substrate surfaces such as Fiberglass or Carbon Filer. | 10-15 |

| SMA 500 |

Aluminum Oxide 500 |

9.0 | SMA 500 is used for very delicate processing, such as turbines, which need to minimize surface painting removal. SMA 500 is suitable for industrial surface treatment with high sensitivity or repainting on existing coatings. |

4-8 |

※ In addition to aluminum oxide, Sponge Media uses garnet, steel Grit, glass bead, etc.

as abrasives and can be applied to various purposes.

Sponge Media Applicator (ES 100 & ES 200)

Portable ESE Sponge Media Applicator

- ES 200 is designed for optimal performance of Sponge Media in all blasting environments.

- Internal stirring assembly ensures stable supply of Sponge Media.

- Adjusting the blasting pressure and media supply speed to the proper conditions shows the maximum efficiency.

- The emergency stop button and the Deadman handle control system provide operator safety.

- It is convenient to procure parts using standardized parts.

- The whole system is operated only by pneumatics, so maintenance is convenient.

Sponge Media Recycler ERP 1000

Portable ESE Sponge Media Recycler

- This is an equipment that allows the Sponge Media, which has already been used for blasting, to be separated into usable particles and foreign substances for reuse.

- Designed to efficiently reduce Sponge Media usage through reuse.

- Sponge Media can be reused up to 10 times using ERP 1000.

- Transportation, handling and disposal costs can be drastically reduced compared to Sand blast.

ERP 1000 unique features include

Compact and efficient design

Compact and efficient design Lightweight equipment for easy movement and installation

Lightweight equipment for easy movement and installation Easy to check and clean equipment

Easy to check and clean equipment Excellent recycling speed

Excellent recycling speed

#esesolution #sponge blast #low dust blast #sponge media #sponge abrasive #sponge blast equipment #sponge blasting #spongeblast #spongemedia #spongeblasting